GI SQUARE PIPES

Price 100.0 INR/ Kilograms

GI SQUARE PIPES Specification

- Surface Treatment

- Galvanized

- Usage

- GI Square Pipes are commonly used as Solar Structures, for structural support, framework, and aesthetic applications, offering both strength and resistance to rust and environmental damage.

- Alloy

- Mild Steel Galvanized

- Product Type

- Steel

- Grade

- ASTM A123 | BSEN ISO 1461 | IS 2629/2633/4759/6745

- Shape

- Other

- Length

- 6 Meter (m)

- Width

- 40 to 300 Millimeter (mm)

- Application

- Galvanized square tube is widely used, in addition to water, gas, oil and other general low-pressure fluid pipeline, but also for the oil industry, especially offshore oil wells, pipeline, Pipe with the tube, as well as the bridge bridge pile, mine tunnel support frame with the tube.

- Color

- grey

GI SQUARE PIPES Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1000 Kilograms Per Week

- Delivery Time

- 3 Days

- Main Domestic Market

- All India

About GI SQUARE PIPES

Galvanized square tube is widely used, in addition to water, gas, oil and other general low-pressure fluid pipeline, but also for the oil industry, especially offshore oil wells, pipeline, Pipe with the tube, as well as the bridge bridge pile, mine tunnel support frame with the tube.

Available in - 20 x 20mm to 300 x 300mm

Versatile Structural Solutions

GI Square Pipes are engineered for versatility, making them a preferred option for applications ranging from solar structures to supporting frameworks in bridges, tunnels, and industrial installations. Their robust design ensures safe and sustainable performances in both commercial and residential settings.

Advanced Galvanized Protection

With a superior galvanized coating, these pipes shield against rust and environmental damage, significantly increasing service life even in challenging climate conditions. This advanced surface treatment also maintains the pipes grey aesthetic, reducing the need for frequent maintenance.

FAQs of GI SQUARE PIPES:

Q: How are GI Square Pipes manufactured and treated for durability?

A: These pipes are made from mild steel and undergo a galvanization process, which involves coating the pipes with a layer of zinc. This treatment enhances their resistance to rust, corrosion, and environmental factors, ensuring long-lasting strength in diverse outdoor and industrial applications.Q: What are the typical uses for GI Square Pipes?

A: GI Square Pipes are commonly utilized in constructing solar structures, offering reliable structural support and framework for buildings, bridges, and tunnels. They are also used for water, gas, and oil pipelines, particularly in offshore oil industry applications.Q: When should I choose galvanized square pipes over other materials?

A: Galvanized square pipes are ideal when you require a combination of mechanical strength and resistance to corrosionespecially in settings exposed to moisture or harsh weather, such as outdoor frameworks and coastal structures.Q: Where can GI Square Pipes be installed?

A: These pipes are suitable for a wide array of environments, including residential and commercial buildings, industrial plants, bridges, mines, tunnels, and solar installations. Their standardized lengths and adaptable width make them easy to incorporate into existing or new structures.Q: What is the process involved in the galvanization of these square pipes?

A: The process follows standards such as ASTM A123 or BSEN ISO 1461 and involves immersing the mild steel pipes in molten zinc. This forms a strong, uniform zinc coating, providing both chemical and physical protection against corrosion.Q: What are the main benefits of using GI Square Pipes?

A: The primary benefits include enhanced durability, corrosion resistance, versatility in application, compliance with international quality standards, and a modern grey finish that remains consistent with minimal upkeep.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Galvanized Products Category

GI ANGLES

Price 80.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Surface Treatment : Galvanized

Application : GI angles have a very wide use with Communication Towers, Railway & Highway Protection, Lamp Posts, Marine Structures, Construction Components, etc.

Alloy : Galvanized Steel

Grade : ASTM A123 | BSEN ISO 1461 | IS 2629/2633/4759/6745

GI ROUND PIPES

Price 100.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Surface Treatment : Galvanized

Application : Sewer lines, fences, railings, scaffolding, and farm irrigation systems

Alloy : Mild Steel

Grade : ASTM A123 | BSEN ISO 1461 | IS 2629/2633/4759/6745

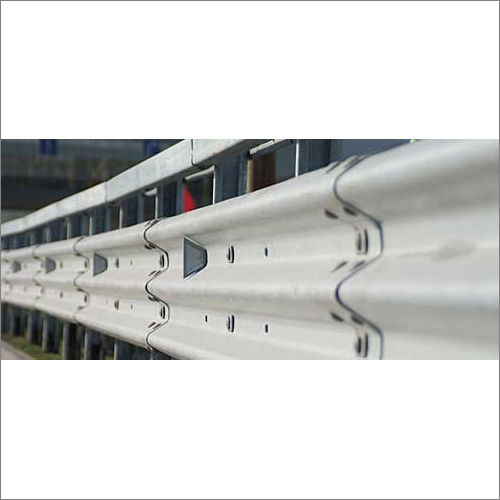

Hot Dip Galvanized W Crash Guard Barrier

Price 120 INR / Kilograms

Minimum Order Quantity : 05 Kilograms

Surface Treatment : Casting

Application : Industrial

Alloy : Steel

Grade : Industrial

Hot Dip Galvanized Round Pipes

Price 100 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Surface Treatment : Galvanized

Application : Sewer lines, fences, railings, scaffolding, and farm irrigation systems

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese