GI ANGLES

Price 80.0 INR/ Kilograms

GI ANGLES Specification

- Alloy

- Galvanized Steel

- Surface Treatment

- Galvanized

- Usage

- GI angles have a very wide use with Communication Towers, Railway & Highway Protection, Lamp Posts, Marine Structures, Construction Components, etc.

- Product Type

- Steel

- Grade

- ASTM A123 | BSEN ISO 1461 | IS 2629/2633/4759/6745

- Thickness

- 3 TO 16 Millimeter (mm)

- Length

- 6 Meter (m)

- Width

- 25 TO 150 Millimeter (mm)

- Application

- GI angles have a very wide use with Communication Towers, Railway & Highway Protection, Lamp Posts, Marine Structures, Construction Components, etc.

- Color

- Grey

GI ANGLES Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1000 Kilograms Per Week

- Delivery Time

- 3 Days

- Main Domestic Market

- All India, Gujarat, Goa, Maharashtra

About GI ANGLES

GI ANGLES have a very wide use with tower, communication tower, railway and highway protection, lamp posts, Marine structures, construction steel structure component, ancillary facilities of substation, light industry, etc.Available in - 25 X 25 X 3 MM TO 75 X 75 X 10 MM

Versatile Applications Across Industries

GI Angles are trusted for an extensive range of uses, such as reinforcing communication towers, providing safety barriers along highways and railways, supporting lamp posts, and strengthening marine and various construction structures. Their adaptability enhances safety and structural integrity in many sectors, whether exposed to urban or coastal environments.

Superior Protection with Galvanization

Galvanization involves coating the steel angles with a protective zinc layer, effectively defending against rust, moisture, and harsh environmental elements. This advanced treatment extends the angles service life and reduces the need for frequent maintenance, making them a cost-efficient choice for long-term projects.

FAQs of GI ANGLES:

Q: How are GI Angles manufactured and treated for corrosion resistance?

A: GI Angles are produced from galvanized steel, where the steel is coated with a layer of zinc through processes adhering to standards such as ASTM A123 and BSEN ISO 1461. This galvanization process forms a robust shield, protecting the angles from rust and corrosion under demanding outdoor conditions.Q: What are the typical uses of GI Angles in infrastructure projects?

A: GI Angles are widely used for building communication towers, railway and highway protection barriers, lamp posts, marine structures, and construction frameworks. Their strength and resistance to environmental factors make them a reliable choice for both urban and coastal installations.Q: When should you choose galvanized GI Angles over other materials?

A: Galvanized GI Angles are preferred when exposure to moisture, marine air, or outdoor environments is a concern. Their corrosion resistance ensures longevity, making them advantageous for projects where durability and minimal upkeep are priorities.Q: Where can GI Angles be sourced or supplied from in India?

A: Manufacturers and suppliers across India provide GI Angles, often customized to specific size and grade requirements. These are available for delivery nationwide to meet the needs of diverse infrastructure and construction projects.Q: What grades and specifications do GI Angles comply with?

A: GI Angles conform to international standards such as ASTM A123, BSEN ISO 1461, and Indian standards like IS 2629/2633/4759/6745, ensuring consistent quality, reliable performance, and compatibility with industry requirements.Q: How does the size range of GI Angles benefit project design?

A: With widths from 25 to 150 mm and thicknesses between 3 to 16 mm, GI Angles offer significant design flexibility. Their standard 6-meter length allows for easier handling and adaptation across various construction and infrastructure scenarios.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Galvanized Products Category

GI ROUND PIPES

Price 100.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Application : Sewer lines, fences, railings, scaffolding, and farm irrigation systems

Surface Treatment : Galvanized

Alloy : Mild Steel

Product Type : Steel

GI SQUARE PIPES

Price 100.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Application : Galvanized square tube is widely used, in addition to water, gas, oil and other general lowpressure fluid pipeline, but also for the oil industry, especially offshore oil wells, pipeline, Pipe with the tube, as well as the bridge bridge pile, mine tunnel support frame with the tube.

Surface Treatment : Galvanized

Alloy : Mild Steel Galvanized

Product Type : Steel

Hot Dip Galvanized Round Pipes

Price 100 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Application : Sewer lines, fences, railings, scaffolding, and farm irrigation systems

Surface Treatment : Galvanized

Product Type : Steel

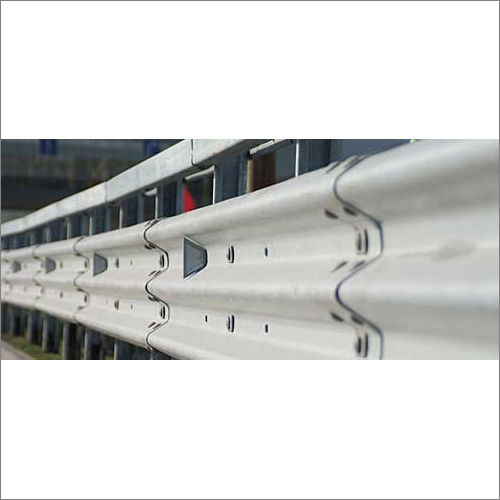

Hot Dip Galvanized W Crash Guard Barrier

Price 120 INR / Kilograms

Minimum Order Quantity : 05 Kilograms

Application : Industrial

Surface Treatment : Casting

Alloy : Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese